QRコード

お問い合わせ

ファックス

+86-579-87223657

住所

中国浙江省金華市武夷県紫陽街Wangda Road

炭化物タンタルム(TAC)はタンタル(TA)と炭素(C)のバイナリ化合物であり、化学式は通常Tacₓ(ここで0.4〜1の範囲)として表されます。これは、優れた硬度、高温安定性、金属導電率を持つ耐火性セラミック材料として分類されます。

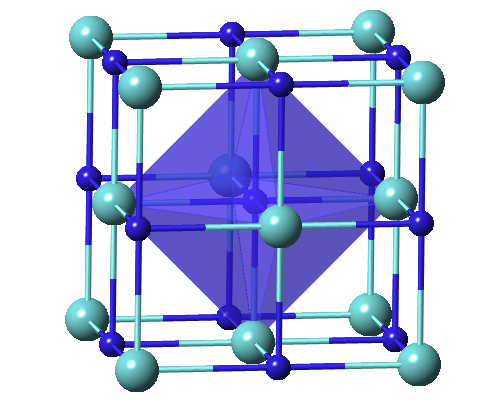

1.1化学組成と結晶構造

炭化物は、タンタル(TA)と炭素(C)で構成されるバイナリセラミック化合物です。

その結晶構造は、顔中心の立方体(FCC)であり、優れた硬度と安定性をもたらします。

1.2結合特性

強力な共有結合により、炭化物は非常に硬く、変形に耐性があります。

TACの拡散係数は非常に低く、高温でも安定したままです。

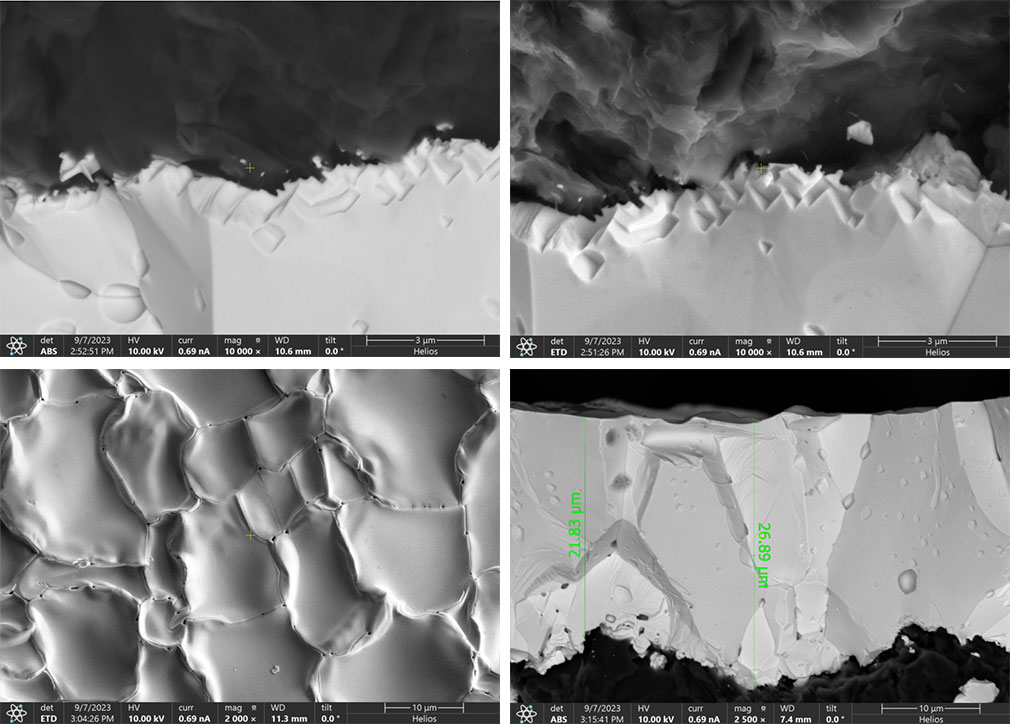

微視的な断面の炭化物(TAC)コーティング

|

物理的特性 |

値 |

|

密度 |

〜14.3 g/cm³ |

|

融点 |

〜3,880°C(非常に高い) |

|

硬度 |

〜9-10 Mohs(〜2,000ビッカーズ) |

|

電気伝導率 |

ハイ(金属のような) |

|

熱伝導率 |

〜21 w/m・k |

|

化学的安定性 |

酸化と腐食に対して非常に耐性があります |

2.1超高融点

融点は3,880°Cの融点で、炭化物は既知の材料の中で最も高い融点の1つであり、極端な温度で優れた安定性をもたらします。

2.2優れた硬度

約9〜10のMOHSの硬度により、ダイヤモンドに近いため、耐摩耗性のコーティングで広く使用されています。

2.3良好な電気伝導率

ほとんどのセラミック材料とは異なり、TACは高金属のような電気伝導率を備えているため、特定の電子機器の用途に価値があります。

2.4腐食と酸化抵抗

TACは酸腐食に対して非常に耐性があり、長期にわたって過酷な環境での構造的完全性を維持しています。 ただし、TACは、1,500°Cを超える空気中で、五酸化タンタル(Ta₂o₅)に酸化する場合があります。

3.1炭化物コーティングされた部品

● CVD Tantal Carbide Coated Compentor:半導体エピタキシーおよび高温処理で使用。

● 炭化物コーティングされたグラファイト部品のタンタルム:高温炉およびウェーハ処理チャンバーで使用されます。例には、炭化物コーティングされた多孔質グラファイトが含まれます。これは、SIC結晶成長中のガスの流れを最適化し、熱ストレスを減らし、熱均一性を改善し、耐性耐性の向上を阻害し、不純物拡散を阻害することにより、プロセス効率と結晶の品質を大幅に改善します。

● タンタル炭化物コーティングされた回転プレート:VeteksemiconのTACコーティングされた回転プレートは、5ppm未満の不純物含有量と密な均一な構造を持つ高純度組成と、LPE EPIシステム、Aixtron System、Nuflare System、Tel CVDシステム、VEECOシステム、TSIシステムで広く使用されています。システム、TSIシステム。

● TACコーティングヒーター:TACコーティングの非常に高い融点(〜3880°C)の組み合わせにより、特に窒化ガリウム(GAN)エピタキシャル層の成長(GAN)の成長(MOCVD)プロセスの成長において、非常に高温で動作することができます。

● 炭化物コーティングるつぼ:CVD TACコーティングされたるつぼは、PVTによるSIC単結晶の成長において重要な役割を果たすことがよくあります。

3.2切削工具と耐摩耗性コンポーネント

●炭化物コーティングされた炭化物切削工具:ツールの寿命と機械加工の精度を向上させます。

●航空宇宙ノズルとヒートシールド:極端な熱および腐食性環境で保護を提供します。

3.3炭化物のタンタル高性能セラミック製品

●宇宙船熱保護システム(TPS):宇宙船および過敏な車両用。

●核燃料コーティング:核燃料ペレットを腐食から保護します。

4.1エピタキシャルプロセスのための炭化物コーティングされたキャリア(容疑者)

役割:グラファイトキャリアに適用される炭化物コーティングは、化学蒸気堆積(CVD)および金属有機化学蒸気堆積(MOCVD)プロセスの熱均一性と化学的安定性を改善します。

利点:プロセス汚染の減少と拡張キャリア寿命。

4.2エッチングおよび堆積コンポーネント

ウェーハトランスファーリングとシールド:炭化物のコーティングは、プラズマエッチングチャンバーの耐久性を改善します。

利点:積極的なエッチング環境に耐え、汚染物質の降水量を減らします。

4.3高温加熱要素

SIC CVD成長への応用:炭化物コーティングされた加熱要素は、炭化シリコン(SIC)ウェーハ製造プロセスの安定性と効率を改善します。

4.4半導体製造装置用の保護コーティング

なぜTACコーティングが必要なのですか? 半導体の製造には極端な温度と腐食性ガスが含まれ、炭化物のタンタルcartは、機器の安定性と寿命を改善するのに効果的です。

セミコンは、大手メーカーでありサプライヤーです炭化物コーティング中国の半導体産業の材料。当社の主な製品には、CVD炭化物コーティング部品、SIC結晶成長または半導体エピタキシープロセスのための焼結TACコーティング部品が含まれます。 Veteksemiconは、継続的なR&Dと技術の反復を通じて、炭化物コーティング業界のイノベーターおよびリーダーになることを約束しています。

+86-579-87223657

中国浙江省金華市武夷県紫陽街Wangda Road

Copyright © 2024 VeTek Semiconductor Technology Co., Ltd.全著作権所有。

Links | Sitemap | RSS | XML | プライバシーポリシー |